Growing a Nobler Fir: Nursery Farms – A Changing Industry

The nursery industry, Oregon’s top agricultural money maker, stands to lose a lot in the face of a changing climate. Leaders in the industry are acting collaboratively to change business-as-usual.

Carson Lord weaves around whispery Japanese Maples and whimsical Pom-Pom Pines. His professional wire-rimmed glasses glint in the sun as he narrates the surrounding farmscape. Weeping Giant Sequoias stretch and swoop from the distance, resembling old-world wizards; nearby Blue Plume False Cypress buoyantly burst from pots.

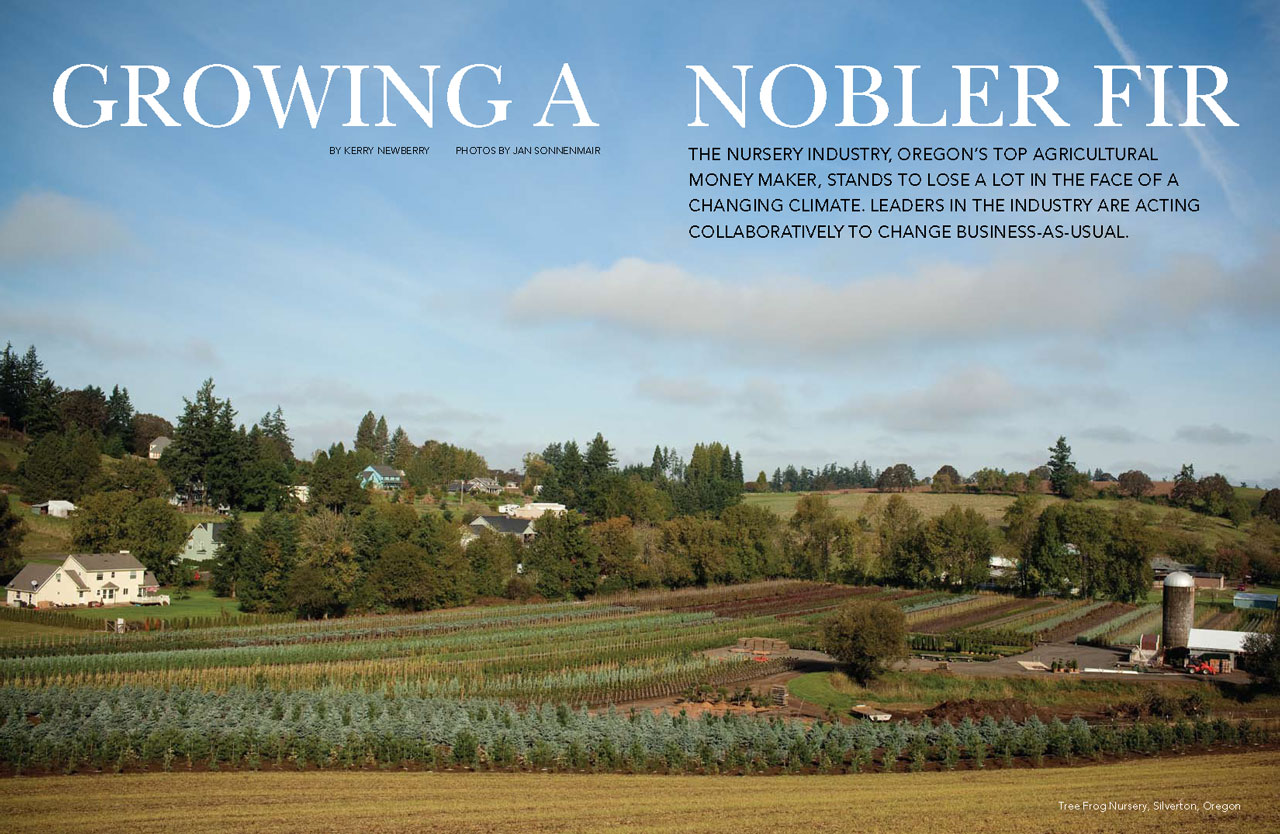

Tree Frog Nursery is tucked into the rolling hillside just outside of Silverton. “My Dad and I started as a hobby—an acre here, an acre there,” says Lord, the owner of the family-owned and operated wholesale nursery stock farm. Fifty acres now comprise the operation, which focuses on the production of woody ornamentals, including roughly 60 varieties of grafted conifers, Japanese maples, boxwood—a cool-season evergreen shrub, and topiaries—sculptured trees reminiscent of the illustrated tuft-like trees of Dr. Seuss.

The scene is bucolic but the industry is big business. According to the Oregon Association of Nurseries, nursery sales averaged about $744 million in 2010; in 2008, the sales crested a billion dollars. The nursery industry is Oregon’s largest agricultural commodity. Working on relatively few agricultural acres, nursery operations yield a comparatively enormous amount of productivity and profit for the state. (Hay is the second largest agricultural commodity in Oregon, and it spans a whopping total of 1,030,000 acres—almost eleven times the 94,250 acres of nursery crops and cut Christmas trees.) The state’s 2,130 nursery and greenhouses also employ more than 20,000 workers.

Oregon ranks as the second largest nursery state in the country and the largest exporter of nursery stock. Nursery stock grows much faster in here than in other parts of the country as a result of Oregon’s long and mild growing season. Growers here can produce a plant ready to purchase in three years, versus the five or six years it takes elsewhere.

Oregon ranks as the second largest nursery state in the country. In 2010, nursery sales averaged $744 million; in 2008, sales crested $1 billion.

“There is a reason apples are grown in Washington and pears are grown outside of Hood River,” says Lord of Tree Frog Nursery. “Certain areas work for certain crops, and that’s certainly true with nurseries.” Some of the best nurseries in the world are located within 45 miles of Portland. (In fact, Marion, Clackamas, Washington, Yamhill and Multnomah Counties were the top five in terms of gross sales of nursery crops in 2009, representing 84 percent of the total value of nursery and greenhouse production in the state.)

The past three years have been a challenging time economically for the nursery industry. Industry sales are down by 30 percent from where they were two years ago. “The downturn of the housing market really hit our industry hard— it’s been tough,” says Whitney Rideout, Business Development Manager for the Oregon Association of Nurseries (OAN).

“It’s important when times are tight right now,” says Lord, “to be as efficient as possible.”

In 2009, the OAN and the Oregon Environmental Council (OEC) announced the start of a collaborative three-year project—the Climate Friendly Nurseries Project. The central goal of the project is to help participating nurseries reduce energy use, resource inputs and greenhouse gas (GHG) emissions while achieving greater economic efficiency and profitability.

Although nursery farms are not major emitters of greenhouse gas emissions, because most nursery crops have been optimized to fit the Northwest’s climate niche, they stand to lose a lot in the face of a changing climate. Potential impacts to growers include decreased water quality and availability, new pests, weeds and plant diseases, and plant stress.

Allison Hensey, OEC Program Director for Healthy Food and Farms, explains that the nursery industry not only has opportunities to reduce greenhouse gas emissions, but to sequester carbon in soil and plants. This makes the overall potential impact to slow climate change far more significant than for non-agricultural sectors of the economy.

The Climate Friendly Nurseries Project draws on the experience of OEC and Ecos Consulting, who collaborated on the Carbon Neutral Challenge for Oregon Wineries. According to the Oregon Climate Assessment Report, no crop better illustrates the climate sensitivity and risk associated with climate change than Pinot noir, the state’s iconic wine grape. Further increases in temperature could move much of the current acreage planted in the Willamette Valley of this notoriously finicky grape outside of what is considered ideal for Pinot noir. To many, the wine industry is the “canary in the coal mine” for climate change.

In 2007, fourteen wineries in Oregon representing 20 percent of the wine produced in the state initiated the Carbon Neutral Challenge. The wineries reduced their carbon footprints by utilizing a number of low- and high-tech measures, ranging from solar panel installations and tank insulation to replacing mowers and pesticides with grazing sheep and goats.

The Climate Friendly Nurseries Project is poised to follow the success of the Carbon Neutral Challenge for Wineries—now an industry-wide certification program.

firs and dogAt the core of the Climate Friendly Nurseries Project is a team that will help participating nurseries secure grants, low interest loans and tax credits for energy and resource efficiency upgrades and provide technical assistance for the upgrades. “Even though efficiency saves you money in the end, it can be expensive up front, so we want people to be able to afford to do it,” says Hensey of OEC.

Fifteen nurseries have signed up to participate so far. They represent a cross section of the industry, from small scale— like Tree Frog—to some of the largest in Oregon, including Bailey Nurseries, Fisher Farms, J. Frank Schmidt & Son and Monrovia.

A fourth-generation family-owned nursery, Bailey Nurseries is one of the largest wholesale nurseries in the nation. Although the main offices and growing fields are located in Minnesota, the company also operates nurseries on Sauvie Island and in the tiny wine country town of Yamhill. The Yamhill operation has been tendering field production for more than 33 years.

Mike Lee, Production Manager at Bailey’s Oregon properties, guides his pickup truck around the 1400-acre Yamhill propagation facility, which includes four farms.

Annually, more than five million cuttings are grown on ten acres of greenhouse space. In an additional fifteen acres of seedbeds, 2.2 million seedlings are produced. Backed by blue sky, hundreds of neatly potted plants cradled in white containers dot the land like a carefully crafted avant-garde mosaic.

A challenge the nursery growers initially faced in the planning meetings for the Climate Friendly Nurseries Project was that the participating nurseries were wildly different in size and variance of products. But they had one thing in common.

“Electricity is one of our biggest energy costs and most of it is associated with pumping water,” says Lee. After an energy analysis by the Department of Engineering at Oregon State University, the nurseries took a close look at their irrigation practices; to start, many converted to drip irrigation if they hadn’t already. Drip irrigation directly waters the root of the plant—instead of showering the entire plant and surrounding area—using not a drop more or less than is needed.

“Every seminar I’ve been to, the buzz phrase is that water is going to be the petroleum of the 21st century,” says Lee. “Irrigation efficiency” is one of the six best practices outlined in the Climate Friendly Nurseries guide developed by the project. The other best management practices include lighting and sensor retrofits; greenhouse insulation; reuse and recycling; heating, ventilation and air conditioning (HVAC); and variable frequency drives (VFDs).

For additional efficiency in irrigation, many nurseries have recently installed VFDs on all of their irrigation pumps. “Under the old irrigation systems you basically had two settings for your pumps—wide open or off,” says Lee. “What the VFDs do is essentially sense the workload that we are calling for on irrigation and match pump speeds—dramatically reducing electrical consumption,” he adds. Installing the units captures substantial energy savings (30 to 35 percent), and reduces nitrous oxide emissions. Like methane, nitrous oxide is an even more significant greenhouse gas than carbon.

Each pumping station has its own meter, which allows operators to track average usage from one year to the next. “The premise of the project is to get a baseline established, and—as we implement things along the way—look back and say ‘our energy consumption went down by this much,’” says Lee. All participating nurseries have committed to implementing at least one of the six best management practices this year.

By tracking the data tied to a specific effort, nurseries will gain solid data on how much they reduced their energy bill—or fertilizer use—as well as measure how a specific practice reduced greenhouse gas emissions. Collected over the course of the three-year project, this will build a powerful data set for the future of the industry.

A few of the farms Bailey Nurseries manages border the Yamhill River in low riparian areas, adjacent to nearby woods abundant with deer. The deer, of course, like to dine on the nursery plants. “Just by accident we started using buckwheat as a cover crop. Well, deer love it—it’s like candy to them,” says Lee. The nursery crew promptly planted one corner of the field with buckwheat, enticing the deer away from the nursery crop, a supreme example of integrated pest management.

Another technique Bailey, Tree Frog and other nurseries are narrowing in on is reducing fertilizer use and sequestering carbon by building healthy soils with organic matter, including cover crops, manure and organic waste. According to research provided by OAN, agricultural use of nitrogen fertilizer is one of the most significant contributors to agricultural greenhouse gas emissions, and the manufacture of commercial fertilizer is a significant source of global emissions. Lee works with a number of boarding stables within three miles of the nursery to obtain horse manure—a naturally and locally made fertilizer—which he applies to the fields. At Tree Frog, Lord makes his own soil ever year to coddle his potted plant and field production. He blends bark dust, pumice, fertilizer and micronutrients in an old concrete mixer settled into one corner of the property’s original dairy barn.

The question, Lee asks, is “how little fertilizer can we use and still meet our production schedule, while reducing our expenses, runoff and environmental impact?” Over the past year, Bailey has cut its fertilizer bill in half.

“Instead of broadcasting fertilizer over the whole field and covering every square inch, we’ve found we can go to a Band-Aid type application that takes a little bit longer. But the savings on material and reduced runoff is significant,” says Lee. In banding, the nutrients are applied directly to the root zone of the plant.

Another opportunity for industry change stems from a question Lee poses: “Is there something out there that is more sustainable than plastic pots?”

A significant number of nursery operations have moved from traditional field-grown operations to container operations, affording greater water, land and energy efficiency, and the ability to operate near a city center. But this means that the nursery farms use an inordinate number of plastic containers. Recently, the industry has cut down on plastic use by reusing containers when possible, and recycling plastic pots and trays when it’s not.

Research is ongoing for a biodegradable pot with durability and longevity—essential attributes for a product that weathers four seasons and the three-year growing season for a nursery plant. Heritage Seedlings, a family-run nursery in Salem that also participates in the Climate Friendly Nurseries Project, created their own makeshift steam cleaner for their plastic containers. Though upfront capital was required, they’ve found the return on the investment quick—cutting costs for new containers, reducing container waste disposal fees and reducing labor costs associated with weeding.

As part of the overall nursery sustainability initiative, the industry recently voted another energy challenge into play. Through a partnership with the Northwest Energy Efficiency Alliance, the Oregon nursery industry set an energy reduction goal of 25 percent in ten years.

“It’s not 25 percent in one day—we’ve got a ten-year time frame here,” Lee says, with optimistic vision. “Look at what wasn’t around ten years ago,” he says. “Wireless internet, iPods, smart phones—you could go on and on.”

With foresight and fortitude, the nursery industry is poised to make a significant difference by implementing innovative and well-researched climate-friendly agricultural practices, and by providing a model for other agricultural sectors. “The best time to plant a tree was 20 years ago,” reads a Chinese proverb. “The next best time is now.”

Edible Portland | Summer 2011

Click here to read on the Edible Portland website http://edibleportland.com/growing-a-nobler-fir/.

Some favorite places in San Panch

Some favorite places in San Panch